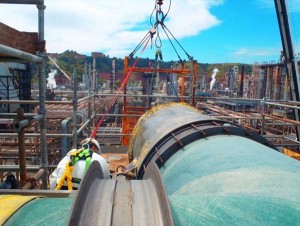

Refinery Cooling Tower FRP Wrap

Only 0.1 inches of steel remaining.

48 inch pipe carrying cooling water.

Leak of 3 drops per second.

Danger of duct breaking in half and

separating from tower.

Safety First!

We hooked the fiberglass laminators to a man-basket during repairs as a contingency in case of tower and scaffolding collapse.

Preparatory Work

We used a combination of resin, fiberglass cloth, and putty to begin to patch the duct without the need for sanding and grinding the rusted metal, which could significantly increase the possibility of additional leaks.

Water-absorbing resin (top of frame)

Fiberglass cloth (right side of frame)

Putty (bottom center- light brown material) made up of resin filler.

Gaps Filled in Coupling

After cutting and removing bolts in the coupling we filled the resultant gaps to create a smooth surface over which to lay the eventual coating (left image). We then used putty along clamp edges to reduce sharp corners for the subsequent layers of fiberglass (center image). Our OSHA certified technician works on early layers of fiberglass around the smoothed corners created by prior steps, smooth corners and surfaces are essential to create strong inter-laminate layer bonding (right image).

Steel Clamp is Bonded to Fiberglass

You must be logged in to post a comment.