FRP Lining Preparation and Lamination Study

Poor Preparation of FRP Lamination Surface and Solution

Poor Preparation of FRP Lamination Surface and Solution

Due to Poor Preparation and Lamination, our client had issues with leaks at the scrubber to inlet joint area visible in the photo to the left.

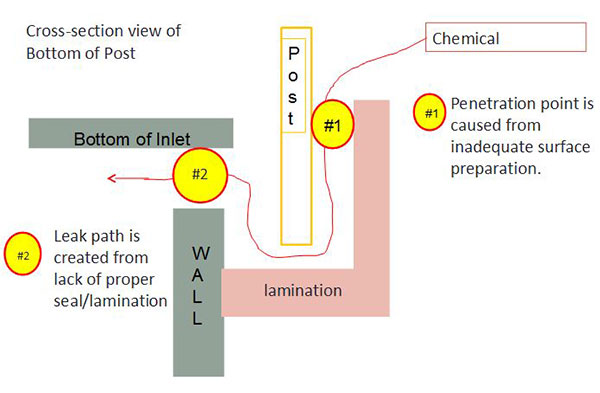

Hypothesis

Our initial hypothesis is best explained by the simple graphic below.

Lamination Penetration Discovery Phase

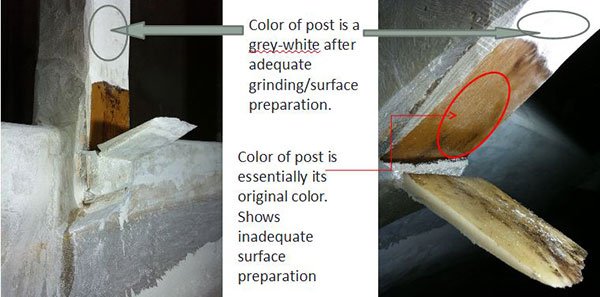

Upon arrival at the site we noted signs of poor lamination which prompted

a series of grinding steps to reveal liquid penetration points.

After 2nd Grinding More Liquid is Revealed Inside Joint

Evidence of liquid inside joint. |

Liquid draining from joint. |

Leak Penetration Point Found

Lamination over post peeled off easily with light prying due to poor surface preparation.

Leak Path After Penetration Point Found

There was no lamination of the wall to inlet directly behind the post. The post installation technique should have been:

- Laminate to seal off inlet to scrubber wall joint (putty & laminate) – only putty was used.

- Place post and put a laminate over the post.

After 3rd grinding the bottom of the middle post was cut 6″ from bottom. |

It was noted that there was no laminate directly behind the post (bad) |

Further grinding revealed a lot of liquid inside the post to wall joint. |

FRP Lining Repairs Made

FRP Lining Repairs Made

- Cut post ~6″ from bottom.

- Surface preparation to obtain good adhesion.

- Seal off inlet to wall joint (at bottom of inlet)

- Laminate joint from inlet to scrubber

- Bottom horizontal joint.

- Minimum 4′ on the vertical joint.

- Install Post – Post to scrubber wall connection at inlet

* Due to the leaks, a conservative approach was used in

designing the repair patches. Posts, made of pultruded

FRP, which is harder to adhere to, at least 4′ along the

post height was grinded.

You must be logged in to post a comment.