Tank Inspection

In order to provide the highest quality inspection services Picon staffs NACE level 3 inspectors and FRP experts who meet FRP industry standards for liner inspections.

Introduction to FRP Tank Lining and When to Consider Tank Refurbish

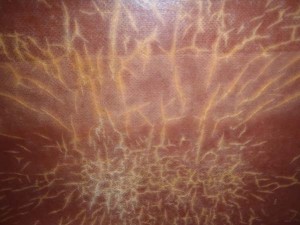

FRP tank linings are composed of 3 layers between the chemicals which your tank holds and the structure of the tank itself. See image left for information regarding the composition and role of the different layers which are intended to protect the structure of the tank from chemical infiltration.

FRP tank linings are composed of 3 layers between the chemicals which your tank holds and the structure of the tank itself. See image left for information regarding the composition and role of the different layers which are intended to protect the structure of the tank from chemical infiltration.

Chemical penetration into the steructural layer must be avoided due to the low chemical resistance of the structural layer.

Regular inspection of tank linings is extremely important to prevent premature degradation of the structure of the tank.

Multi-Level Inspection Program and Inspection Reporting

We perform a variety of tests to compile information for our clients to guide their maintenance plans for their equipment. In addition to the tests pictured below we also provide Acetone Sensitivity Testing, Chemical Testing (pH, etc.), and Mechanical Structural Analysis.

Click here for More Information on Multi-Level Inspections, Testing & Intervals

|

Pull-Off Adhesion Test |

Barcol Hardness Testing per ASTM

|

Testing for Moisture per ASTM |

|

Peel-Off Adhesion Testing

|

Visual Observation of Liner

|

Analyze Depth of Stress Cracks

|

You must be logged in to post a comment.