Quality Trailer Re-lining Service

Northern California Trailer and Tank Linings

Does quality craftsmanship and materials matter? See for yourself below.

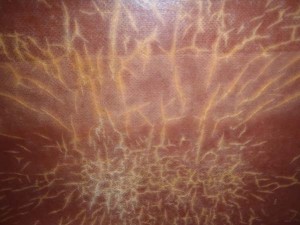

By Picon (After 2 Years) |

Not By Picon (After 2 Years) |

| No noticeable degredation. Large patches with smooth joints are less prone to leaks. | Liner degradation. Many small patches with rough lamination leads to penetrations and leaks. |

|

|

- Abrasive blasting at same facility for steel substrates

- Prevents flash rust build up on surface if abrasive blasting is done at a different facility

- Helps maintain NACE surface preparation standards

Specialty abrasives are selected by our engineering staff depending on the substrate

Specialty abrasives are selected by our engineering staff depending on the substrate- Engineering / Quality Control tests

- Surface profile tests (ASTM D4417, NACE)

- Chemical tests – pH, CSN

- Adhesion tests

- Barcol Hardness tests (ASTM D2583)

- Acetone Sensitivity Test

- Dew Point Measurements

-

Dry Film Thickness gage (ASTM D6132)

After Pull-Off Adhesion Test

|

Before Reline

|

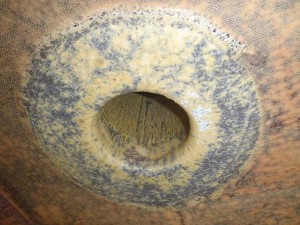

Resin Degradation

|

Chemical Resistance vs Cracks

|

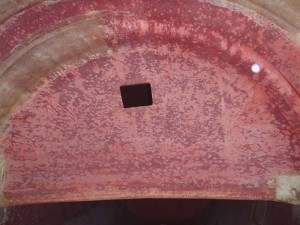

Before Reline

|

After FRP Reline

|

Our Client had a Problem: The Dome Lid Liner, done by another firm in CA, would not close due to improper application.

Steel Substrates

Steps taken to protect trailer exterior |

High Temperature Baked Phenolics

Baked phenolics (e.g. Heresite Plastite) for high % H2SO4 application. |

Plasite 3070 L from Carboline 400 degree F bake, DFT (5-7mils) |

Difference between with and without primer

Difference between with and without primer Nozzles undergo high perturbation stresses

Nozzles undergo high perturbation stresses

You must be logged in to post a comment.